Shanghai HaiJee Intelligent Technology Co., Ltd. is located in the international financial center: Shanghai, China. Our company focuses on providing high-end equipment, system integration and technical services for Chinese and global users, and continues to create value for users in fine chemicals, medicine, food and other fields.

The core team of the company is composed of a number of mechanical engineers and electrical engineers with more than 10 years of experience. It can provide customized single equipment and automatic intelligent production lines and services according to the process requirements and output of users.

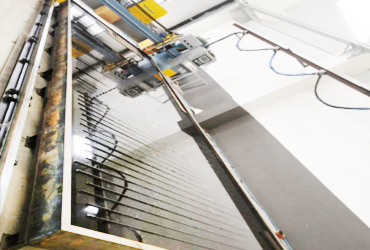

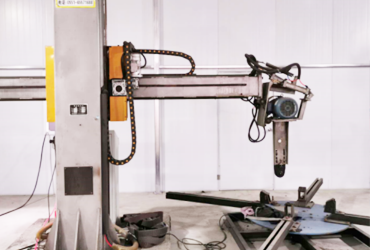

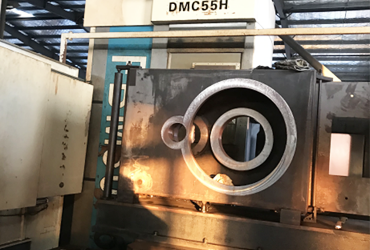

Haijee production base (Dingjee intelligent) covers an area of more than 10000 square meters, mainly engaged in the R & D and manufacturing of large vessels, agitators, reactors and other mechanical equipment; It has large-scale lifting equipment, large-scale CNC boring and milling machines, CNC machining centers, large-scale lathes, cylindrical grinders, full-automatic plasma, flame cutting machines, plate shears, bending machines, hydraulic plate bending machines and other processing equipment, as well as various advanced detection instruments such as metal spectrum analyzers, ultrasonic thickness meters, surface roughness detectors, dynamic balance testers, etc.

Our Goal: to provide users with products and services with excellent performance, reliable quality and the most cost-effective!

R&D Center and Experimental Center

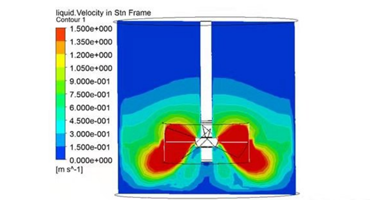

Flow field analysis CFD

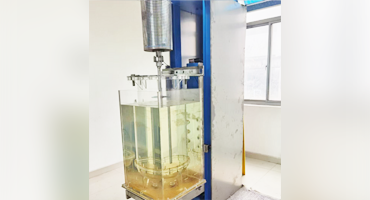

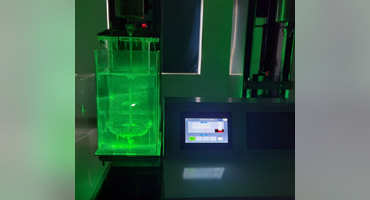

Mixing testing center

Mixing testing center

Company strength

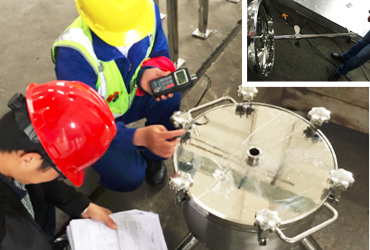

Testing instruments & Machining equipment

Quality assurance

The workshop is fully equipped with various hardware. The assembly group includes automatic feed drilling machine, high-speed drilling machine, profile cutting machine, rocker drilling machine, cylindrical grinder, etc. The metalworking group includes electric discharge numerical control cutting machine tools, table- grinding machines, lathes, milling machines, etc. Cold working group: symmetrical up regulation three roll plate bending machine, DC argon arc welding machine, plate bending machine, cantilever crane, self-commissioning roller frame. Blanking group: plasma cutting machine, hydraulic bending machine, hydraulic gate plate cutting machine. Polishing group: Mobile-polishing machine, head-polishing machine, tank-polishing machine.

The company has high-precision measurement tools and equipment, such as CMM, digital height gauge, metal spectrum analyzer, ultrasonic thickness gauge, surface roughness tester, dynamic and static balance tester, which are specially used for precision machinery detection.

Materials: the basic raw materials are all high-quality products at home and abroad, and the motor, frequency converter, bearing, electrical components and other standard parts are all international famous brands.

Design and processing personnel: all the designers have intermediate and senior titles, and have more than five years of practice and design experience in the industry. The production personnel are skilled workers with more than six years of experience.

Project-manager-responsibility-system: each of our contract projects has a special project manager who is responsible for the whole process. After signing the contract, the project manager will undertake:

The following 22 responsibilities:

1. Transfer customer data with the sales representative (intervene in the technical negotiation stage)

2. Contract handover

3. Project design assignment

4. Project design instruction

5. Project schedule

6. Project drawing design (including 3D drawings delivered to the owner)

7. List of purchased parts, standard parts and manufacturers

8. List and price of vulnerable parts

9. Production operation instructions

10. Design guidance

11. Packaging and transportation instructions

12. Preparation of customer manual

13. Production schedule

14. Analysis of abnormal production

15. Product instruction

16. Product quality inspection sheet

17. Project installation schedule

18. Project installation personnel induction training schedule

19. Induction training manual for engineering installation personnel

20. Project acceptance sheet

21. Project lesson and learn

22. Regular return visit and full after-sales tracking

warranty service

You can call the service hotline at any time: 021-66781837. Professional engineers will answer your questions at any time; If not reply immediately, we promise to reply you within 2 hours; If we can't answer by phone and we have to have technicians on site, our after-sales service personnel promise to arrive at the site within 24 hours to solve your problems.

Free Service Items within the Warranty

Free technical guidance service

Regular on-site visit

All parts and components damaged by non-human factors (improper operation) shall be replaced free of charge

Product recall policy

Spare parts Inventory