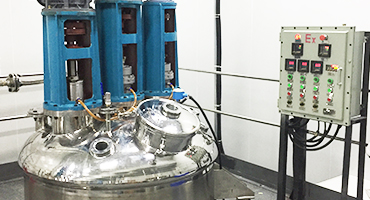

High-speed Disperser (Hydraulic Lifting)

▌Product Introduction

The hydraulic lifting disperser is mainly used for crushing, dispersing, emulsifying and mixing the liquid raw materials with different viscosity. Through the high-speed operation of the new high-efficiency upper and lower sawtooth of the dispersing disc, it can shear, impact, crush and disperse the materials at high speed, so as to achieve the functions of rapid mixing, dissolution, dispersion and refinement.

▌Product Features

1. This machine is suitable for large-scale industrial production, hydraulic lifting - steady and reliable;

2. The airtight design can reduce solvent volatilization and material loss, also save environmental protection;

3. Automatic control, temperature and pressure automatic feedback system to ensure safety

4. The sealing and explosion-proof performance can be customized;

5. Floor installation or platform installation can be selected;

6. Ordinary type or different clamping as belt, pneumatic and manual holding.

▌Technical Parameter

|

Model |

Power(kw) |

Speed(rpm) |

Stroke(mm) |

Capacity(L) |

Diameter of disc(mm) |

Hydraulic station power(KW) |

|

HJFS-2.2 |

2.2 |

0-1440 |

600 |

50~150 |

150 |

0.75 |

|

HJFS-4 |

4 |

0-1440 |

600 |

50~200 |

200 |

0.75 |

|

HJFS-5.5 |

5.5 |

0-1440 |

800 |

80~250 |

200 |

0.75 |

|

HJFS-7.5 |

7.5 |

0-1440 |

800 |

100~300 |

250 |

0.75 |

|

HJFS-11 |

11 |

0-1440 |

800 |

100~400 |

250 |

0.75 |

|

HJFS-15 |

15 |

0-1440 |

800 |

150~500 |

300 |

0.75 |

|

HJFS-18.5 |

18.5 |

0-1440 |

1100 |

200~800 |

300 |

1.1 |

|

HJFS-22 |

22 |

0-1440 |

1100 |

200~1000 |

300 |

1.1 |

|

HJFS-30 |

30 |

0-1440 |

1100 |

300~1500 |

350 |

1.1 |

|

HJFS-37 |

37 |

0-1440 |

1100 |

400~2000 |

400 |

1.5 |

|

HJFS-45 |

45 |

0-1440 |

1300 |

500~2500 |

450 |

1.5 |

|

HJFS-55 |

55 |

0-1440 |

1300 |

600~3000 |

450 |

1.5 |

|

HJFS-75 |

75 |

0-960 |

|

800~4000 |

500 |

2.2 |

|

HJFS-90 |

90 |

0-960 |

|

1000~5000 |

550 |

2.2 |

|

HJFS-110 |

110 |

0-960 |

|

1000~6000 |

550 |

2.2 |

|

HJFS-132 |

132 |

0-960 |

|

1500~8000 |

600 |

2.2 |

▌Remarks

1. The maximum capacity is water as the reference medium;

2. High temperature, high pressure, explosion-proof, flammable, corrosive environment can be customized.

The disperser is suitable for dispersing, mixing materials in industries such as paint, ink, dye, ink, color printing, medicine, cosmetics and etc.. Our technology engineers will provide you all-sided solution according to the required capacity, different equipment form or size, treatable material characteristics.