Industrial horizontal sand mill

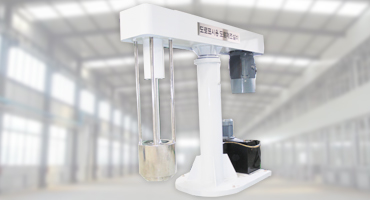

▌Product Introduction(Horizontal sand mill (Disk type))

The new disc type horizontal sand mill, with industrial design, better mechanical structure and higher efficiency, is widely used in medium and low viscosity materials such as paint, ink, pesticide suspension, color paste, carbon black, industrial paint, automotive paint, latex paint, titanium dioxide, etc. The internal structure is relatively stable. Double end cartridge mechanical seal is adopted. The equipment has good grinding material fineness, high cost performance, beautiful appearance, compact structure, simple operation and high reliability.

▌Product Advantages

1. Fully enclosed and continuous operation, large batch of treatment, and environmentally friendly;

2. According to different materials, the structure of dispersion disc can be selected, including disc type, triangular eccentric type, etc;

3. According to different materials, centrifugal screen discharging mode or slot dynamic discharging mode can be selected;

4. Gap type discharge mode, with large flow, can choose smaller particle size grinding medium;

5. The dynamic discharge separator is self-cleaning, non-clogging and super wear-resistant;

6. The barrel and grinding parts can be made of wear-resistant alloy steel, high-density polyurethane and precision zirconia;

7. The unique vortex channel design makes the equipment have a good cooling effect;

8. Double end mechanical seal to ensure material safety during operation;

9. Material temperature, material pressure, water pressure and air pressure are protected to ensure the safety of the process.

▌Technical Parameter

|

Model |

Capacity(L) |

Power (KW) |

Batch Capacity (L) |

Linear Speed(m/s) |

Ball Size(mm) |

Overall Dimension (mm) |

Weight (KG) |

|

HJSM-5 |

5 |

5.5 |

40-120 |

8 |

0.6-2.5 |

1050*950*1400 |

550 |

|

HJSM-10 |

10 |

11 |

60-200 |

8 |

0.6-2.5 |

1050*950*1400 |

600 |

|

HJSM-30 |

30 |

18.5 |

240-450 |

8 |

0.6-2.5 |

2150*780*1350 |

1090 |

|

HJSM-50 |

50 |

30 |

350-700 |

11 |

0.6-2.5 |

2500*750*1560 |

1350 |

|

HJSM-80 |

80 |

37 |

450-850 |

11 |

0.6-2.5 |

2550*1200*1100 |

1800 |

|

HJSM-100 |

100 |

55 |

650-1100 |

11 |

0.6-2.5 |

2600*1200*1500 |

2100 |

▌Product Introduction(Horizontal sand mill (Pin type))

High efficiency pin type horizontal sand mill adopts a bar pin with special shape design to strengthen the impact and shearing effect of grinding beads on materials. It can use dynamic self-cleaning slot type discharge for a wide range of materials with medium low viscosity and high solid content, such as printing ink, flexible relief oil ink, automobile repair paint, color paste, ordinary electronic paste, graphite paste, etc.

▌Product Advantages

1. The rotor is equipped with an internal cooling system to effectively control the temperature generated in the grinding process, which is suitable for grinding heat sensitive materials;

2. The rod pin type grinding structure strengthens the impact and crushing effect of grinding beads on materials. With its high energy density, it is suitable for grinding materials that are difficult to disperse;

3. The grinding cylinder body is made of high wear-resistant alloy steel, free of metal pollution and discoloration, and can be made of PU, ceramics and other materials;

4. The slot type dynamic separator has self-cleaning ability, is not easy to block, and has a long service life;

5. The diameter of grinding medium can be selected as 0.6mm, with high grinding efficiency;

6. With water temperature, material temperature, material pressure, water pressure, air pressure and other real-time monitoring and protection systems to ensure the normal operation of the equipment;

7. Pneumatic diaphragm pump, screw pump, gear pump, etc. can be selected according to the characteristics of customer materials.

▌Technical Parameter

|

Model |

Capacity(L) |

Power(KW) |

Batch Capacity(L) |

Linear Speed(m/s) |

Ball Size(mm) |

Overall Dimension(mm) |

Weight(KG) |

|

HJSM-R15 |

15 |

11 |

60-200 |

8 |

0.8-2 |

1300*700*1300 |

1300 |

|

HJSM-R20 |

20 |

22 |

80-200 |

8 |

0.8-2 |

1450*800*1450 |

1480 |

|

HJSM-R30 |

30 |

30 |

110-300 |

8 |

0.8-2 |

1700*980*1750 |

2200 |

|

HJSM-R50 |

50 |

45 |

150-400 |

8 |

0.8-2 |

1800*1000*1800 |

2380 |