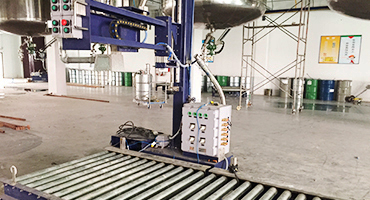

Automatic Liquid Filling Machine

▌Product Introduction:

The filling machine adopts weighing measurement, and it is fully automatic from the use of packaging barrels. It only needs to place barrels of the same specification and model neatly at the front of the barrel loading conveyor line. Under the command of PLC and sensors, professional robots automatically complete the following tasks: barrel sorting, barrel dividing, quantitative filling, automatic cap picking-up, capping, automatic stacking, pallet loading, pallet stacking and automatic delivery out of the packaging line to complete the filling operation.

1. The filling speed is fast and the application scope is wide. Double head or multi head filling are available, and automatic barrel sorting and barrel dividing devices are used to speed up the conveying speed;

2. High degree of automation, saving production costs. The whole filling line only needs people to put the barrels into the track, and then it can realize automatic barrel sorting, automatic barrel separation, automatic filling, automatic cap placement, automatic capping, automatic stacking and other filling operations;

3. High filling precision and high intelligence. The weighing sensor adopts METTLER TOLEDO brand, and the accuracy can reach one thousandth. Equipped with automatic instrument to realize automatic feeding; It has functions such as automatic reset after startup, automatic repair of weight error, power failure protection, and factory settings can be reset after misoperation;

4. High environmental protection index and high safety performance. It can realize rapid filling and capping, reduce volatilization, and the whole line is available for filling.

▌Technical Parameter

|

Type |

Measurement |

Batch capacity L |

Filling Speed drums /h |

Filling accuracy |

Power Kw |

Filled Material |

| Automatic |

Weighing |

10-30 |

500-700 |

0.1% |

55 |

Liquid |

▌Application industry

paint, coating, ink, pesticide, lubricating oil and other liquids.